As amazing as it sounds, 3D printed parts can now talk wirelessly to smart devices without electronics. This means consumers can hook up an attachment to a laundry detergent bottle they print out and it would automatically connect to a smart phone and order more when running low.

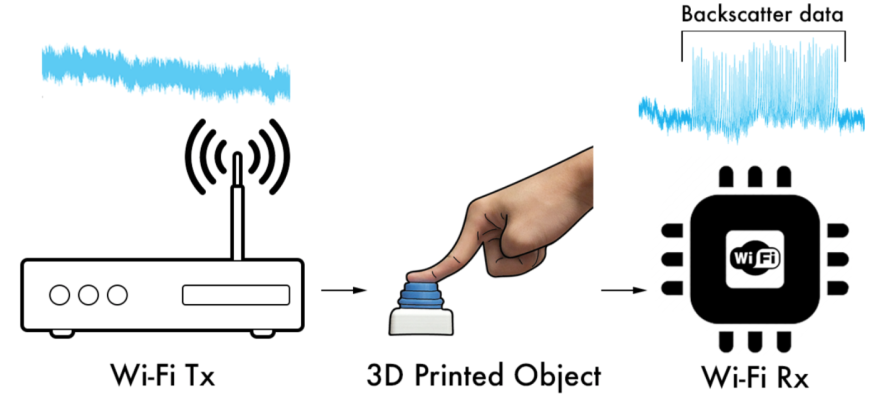

Because 3D printers cannot print objects with radio chips, University of Washington researchers Vikram Iyer, Justin Chan and their team from the UW Networks & Mobile Systems Lab, had to come up with a different way of doing it. They used Backscatter communication. "The solution that we ended up coming up with instead was, to reflect radio signals that are in the environment rather than having a 3D printed device create its own."

https://www.youtube.com/watch?v=u8zMyDXbMMY&feature=youtu.be

Here's how they did it

- They made an antenna out of conductive printing filament contained in the 3D printed object. The antenna transmit data by reflecting radio signals emitted by a WiFi router or other device.

- By pushing a button, turning a knob and other physical motion this triggers gears and springs in the 3D object causing a conductive switch to intermittently connect or disconnect with the antenna and change its reflective state.

- Information is encoded by the presence or absence of the tooth on a gear. Energy from a coiled spring drives the gear system. This creates patterns of reflected signals that can be decoded by a WiFi receiver.

Iyer says it doesn't cost very much to create a part like this. The most expensive thing he says is buying the 3D printer for a couple hundred dollars. Plastic filament is about $30. You would also need conductive filament.

The team is making CAD models of the technology available to the public. "According to Iyer, "Part of the reason we wanted to release it openly to the whole community was to see what other applications people will come up with."

Eventually he'd like to see it work at longer ranges and send more data.

The researchers described their technology in a paper presented Nov. 30 at the Association for Computing Machinery's SIGGRAPH Conference and Exhibition on Computer Graphics and Interactive Techniques in Asia.